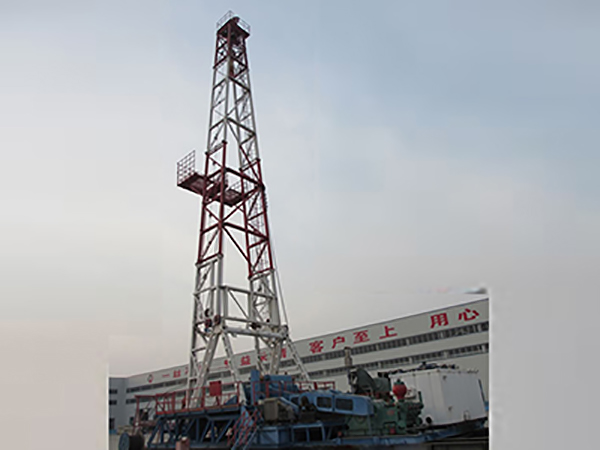

Since petroleum drilling machine came into being, skid-mounted drilling rig has been the basic and most widely used type. Although it is not as easy to be moved as the mobile (self-propelled) drilling machine, skid-mounted drilling machine has flexible structure with steady derrick, powerful drilling capacity and strong adaptive capacity to environment. After AC variable frequency driving is applied into drilling equipment, skid-mounted drilling machine shows more obvious advantages compared with self-propelled drilling machine which has to be equipped with a diesel engine for vehicle running. As the improvement of technology, mounting, dismounting and transport of skid-mounted drilling machine is becoming more and more convenient and efficient.

The ZJ15 skid-mounted drilling rig is a mechanical drive drilling machine designed for coalbed methane well, geothermal well and water well exploitation. Its basic parameters conform to the China national standard of SY/T5600-1999 (Types and Basic Parameters of Petroleum Drilling Machines). Its auxiliary parts complying with specification of API can meet the different drilling technical requirements. The ZJ20 skid-mounted drilling equipment is an improved product developed based on the ZJ15 model. It is suitable for exploiting oil, gas, and water well with the depth of 800m-2000m.

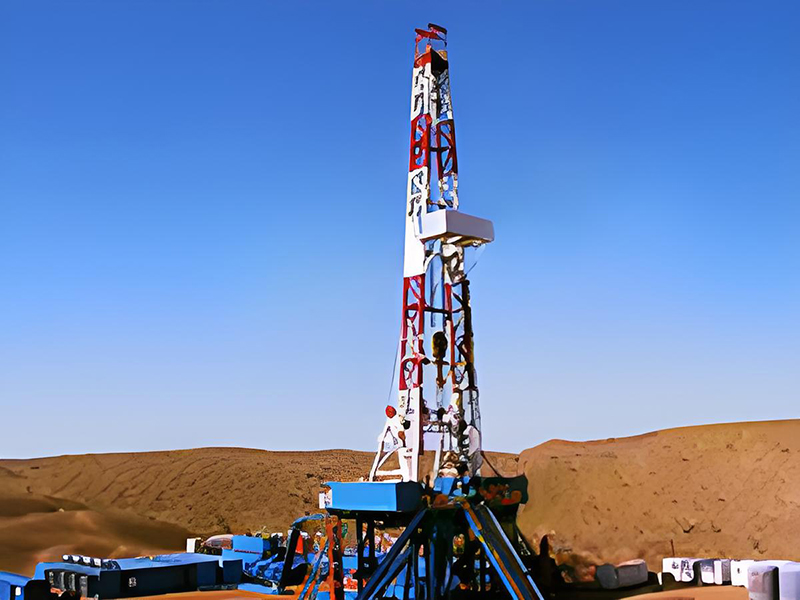

ZJ30 skid-mounted drilling rig is suitable for drilling wells in the depth lower than 3000m. It can work in different sort of environments like shallow sea areas, beaches, desert and cold areas.

The key components of this machine are driven by mechanical transmission. The whole machine is a highly cost effective product which is easy to operate and maintain.

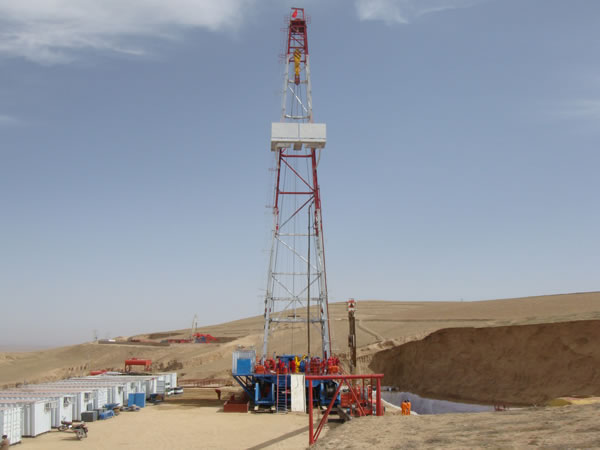

This series of skid-mounted drilling rigs include three models that are respectively ZJ40/2250J, ZJ40/2250LDB and ZJ40/2250L. They are suitable for being applied in drilling engineering to drill wells with the depth lower than 4000m. They can be used in different environments such as shallow sea areas, beaches, desert and cold areas based on the need of customers.

Including models of ZJ50/3150D and ZJ50/3150L, our ZJ50 series skid-mounted drilling rigs can be used to drill wells with the depth not exceeding 5000m. Based on the practical need of customers, they can work in shallow sea areas, beaches, deserts cold areas, etc.

The drawworks and mud pump of our skid-mounted drilling rig adopt hydraulic and compound chain transmissions. 3 sets of A12V190PZL-3 diesel engines and their hydraulic couple reduction gearbox together form the power units. The power unit is assembled on the pedestal of the backstage drill floor.

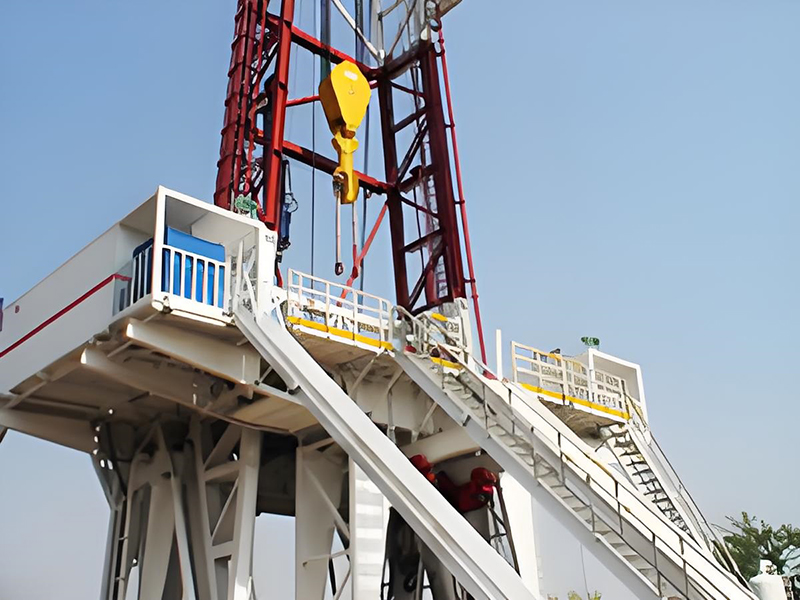

Our skid-mounted drilling rig is composed of several modules that are the derrick, substructure (including basic pedestal, drill floor, the backstage floor) and the pedestal for computer room.

Derrick, which is the most important part of a skid-mounted drilling machine, is mainly used to support lifting devices like the crown block, traveling block and the hook. The derrick can be used to place slurry circulation equipment such as the standpipes, swivel and the water hoses. It has the function of bearing the load generated in operations like tripping in or out the drilling bit, feeding in the casing pipe, and salvaging. Besides, it also provides height and space for tripping in or out as well as placing the drill stand.

SubstructureThe substructure of a skid-mounted drilling rig can be classified into box-on-box type and self-lifting type. The substructure is mainly for placing the derrick, power units, driving system, drawworks, rotary table, drill rod, etc. It also provides space for the drilling operation platform and other wellhead equipment.

Driving SystemWith modular design, the driving system is quite suitable for skid-mounted drilling machine. This system has compact structure and is stable in performance to adapt to the drilling condition and the requirement of frequent movement.

RONGLI Petroleum Machinery is best known for the outstanding performance of its drilling rigs and mud pumps. Remember to browse the online catalogue for excellent deals on the fracturing pump, skid-mounted drilling rig, and much more! RONGLI--deep penetration begins here.

Our company has complete service system. Warranty period starts from the day when machine installation is completed. If the delivery time were delayed for more than 90 days as customer required, warranty period would start from the day when goods are sent out.